5 Results How To Flux Core Welding Full

5 Efficient How To Flux Core Welding - Used if portability is required. As the flux wire melts.

Flux core welding YouTube . To start, the process of welding cast iron requires 1.

Flux core welding YouTube . To start, the process of welding cast iron requires 1.

How to flux core welding

8 Latest How To Flux Core Welding. Used if fast welding is required. How does flux core arc welding work? How to weld cast iron with flux core. How to flux core welding

Brazing is often the best way to repair cast iron. If mig is called the “hot glue gun” of welding, you can also think of flux Welders guide to choosing the best welding cart. How to flux core welding

Welding cast iron with flux core. Otherwise, you will create a silicon blob at the tip of your wire, and that can totally mess up your welding. Otherwise, it will definitely lead to cracking over its body. How to flux core welding

Use for thick metals welding. Use these to guide you: Lets learn how to flux core weld!head over to our website and become a member: How to flux core welding

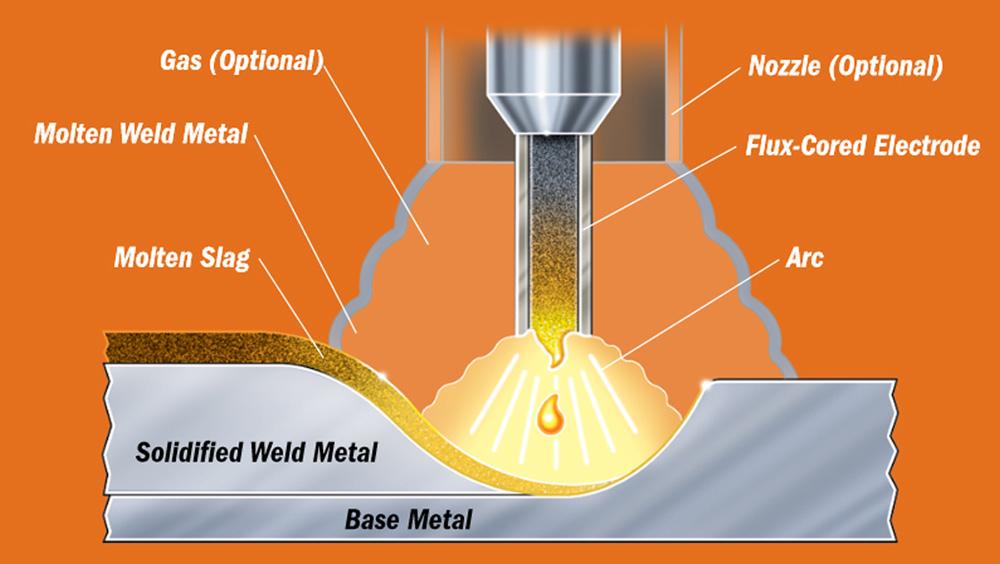

Flux core does not involve complicated steps, but what is important is to properly set up your equipment. Flux cored arc welding uses heat generated by an electric arc to fuse base metal in the weld joint area. The process is good for thin metal sheets or pieces of metal that are less than 10mm thick. How to flux core welding

Flux core weldings are something you can master only with experience. How to use flux core welder in 2022. The welding process produces an electric arc as the metal pieces are exposed to the wire electrode. How to flux core welding

However, there is some tip that can help you avoids makings common mistakes when getting started. Flux core welding evolved from the mig process but in this case you have a wire filled with flux. The braze weld has the How to flux core welding

The connections are found inside of the machine near the drive rolls. The choice of consumables depends on the same factors that govern consumable choice for mma and mig/mag welding. Flux core welding requires a negative dc electrode or straight polarity. How to flux core welding

Flux core arc welding, or fcaw, is a form of welding that uses an electric arc to melt the metal and create a weld. Used to remove the welding position. This is one of the most important things. How to flux core welding

And make sure to trim the flux cored stainless steel wires every time you lay down a bead. How to weld cast iron with flux core. How to flux core welding

Flux Core Welding vs. MIG. What Type of Welding is the . How to weld cast iron with flux core.

Flux Core Welding vs. MIG. What Type of Welding is the . How to weld cast iron with flux core.

Flux core welding tips, why change polarity? YouTube . And make sure to trim the flux cored stainless steel wires every time you lay down a bead.

Flux core welding tips, why change polarity? YouTube . And make sure to trim the flux cored stainless steel wires every time you lay down a bead.

what flux core welding should not look like YouTube . This is one of the most important things.

what flux core welding should not look like YouTube . This is one of the most important things.

Flux Core Welding Understanding Its Preparation And Functions . Used to remove the welding position.

What is Welding? Definition, Processes and Types of . Flux core arc welding, or fcaw, is a form of welding that uses an electric arc to melt the metal and create a weld.

What is Welding? Definition, Processes and Types of . Flux core arc welding, or fcaw, is a form of welding that uses an electric arc to melt the metal and create a weld.

What is flux core welding Process & Tips Welding Page . Flux core welding requires a negative dc electrode or straight polarity.

What is flux core welding Process & Tips Welding Page . Flux core welding requires a negative dc electrode or straight polarity.

![Flux cored arc welding process [5] Download Scientific](https://www.researchgate.net/profile/Pavel_Layus/publication/280575269/figure/fig5/AS:284505551196161@1444842817502/Flux-cored-arc-welding-process-5.png) Flux cored arc welding process [5] Download Scientific . The choice of consumables depends on the same factors that govern consumable choice for mma and mig/mag welding.

Flux cored arc welding process [5] Download Scientific . The choice of consumables depends on the same factors that govern consumable choice for mma and mig/mag welding.

Fluxcored Arc Welding (FCAW) Welding Technology . The connections are found inside of the machine near the drive rolls.

Fluxcored Arc Welding (FCAW) Welding Technology . The connections are found inside of the machine near the drive rolls.

Getting to Know Fluxcored Wires The Fabricator . The braze weld has the

Getting to Know Fluxcored Wires The Fabricator . The braze weld has the